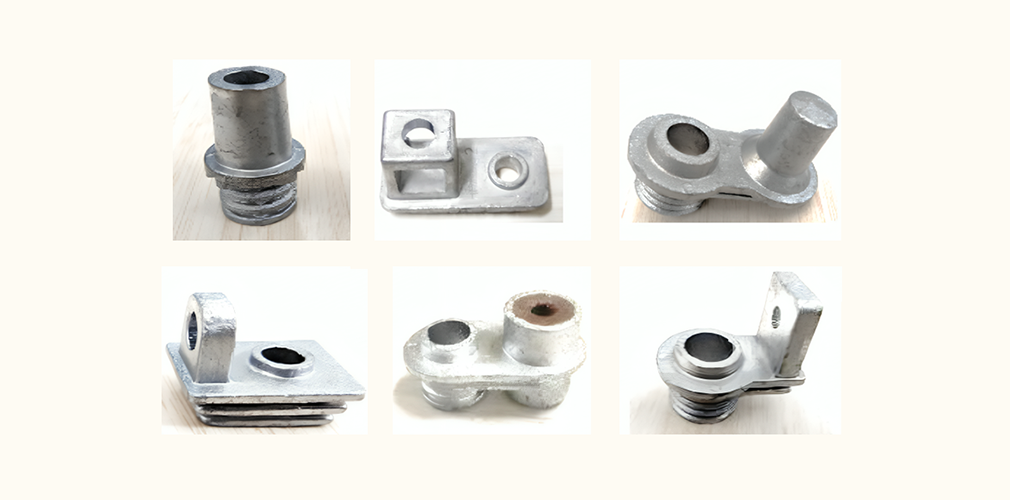

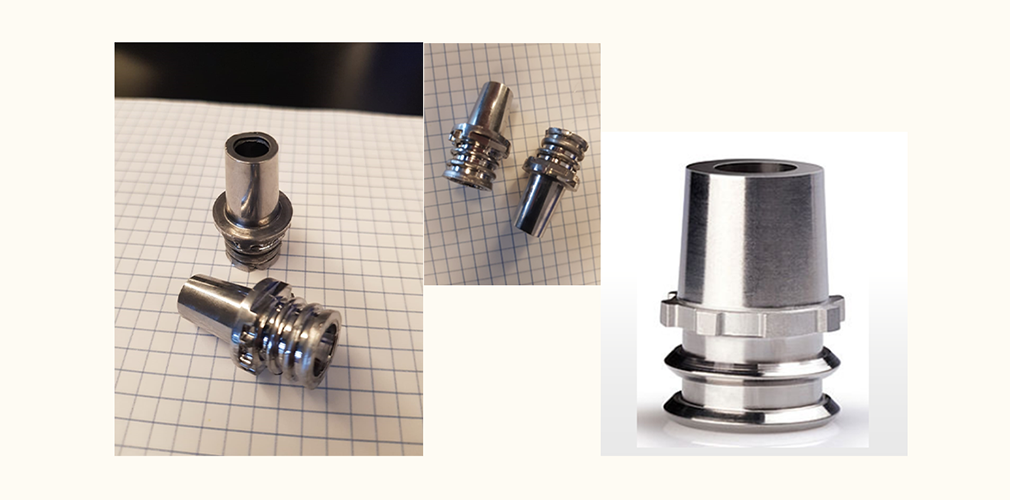

At Mangal Industries, we specialize in producing high-quality two-wheeler, four-wheeler, and industrial bushes for the automotive and industrial sectors. Utilizing advanced manufacturing technologies like cold-forging and pressure die casting, we ensure superior product quality and efficiency, while our stringent quality assurance processes guarantee reliability and excellence in every product.

Industries We Serve

Products & Solutions

Manufacturing Capabilities

At Mangal Industries, we leverage advanced manufacturing technologies to enhance product quality and production efficiency. Our state-of-the-art cold-forging machinery meticulously shapes each bush, ensuring accuracy and enhancing resistance to wear and tear. This process guarantees long-lasting performance, crucial for various industrial applications, while significantly improving the capacities and quality of bushes by eliminating secondary operations and enhancing product appearance.

We boost production output through the utilization of pressure die casting and multi-slide pressure die casting technologies, ensuring superior product quality and manufacturing efficiency. Our auto gravity die-casting machines further elevate quality and operator safety, increasing production output by over 50% compared to manual methods. Additionally, implementing auto leak testing and auto gumming machines for four-wheeler bushes enhances productivity and quality, reinforcing our commitment to excellence.

Quality Assurance

At Mangal Industries, our Quality Assurance process is meticulously designed to ensure the highest standards of product excellence and reliability. This commitment begins with stringent raw material selection, ensuring that only the finest materials are used in our manufacturing processes. Each batch of raw materials undergoes rigorous inspection and testing to meet our stringent quality criteria before entering the production line. During manufacturing, continuous monitoring and quality checks are performed at every stage, ensuring consistency and precision in every product. Utilizing advanced testing technologies such as non-destructive testing (NDT) and automated leak testing, we assess the internal structure and integrity of our products without causing any damage, guaranteeing optimal performance and preventing potential failures in real-world applications.

In addition to these rigorous controls, we implement lean manufacturing principles to continually refine our processes, eliminate waste, and enhance efficiency. We actively seek and analyze customer feedback to identify areas for improvement, ensuring that our products evolve to meet the ever-changing demands of the market.