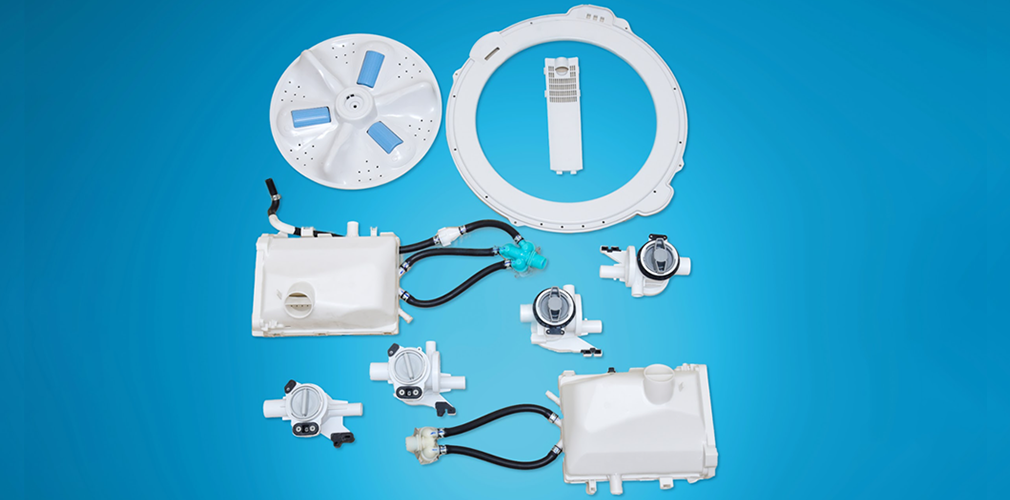

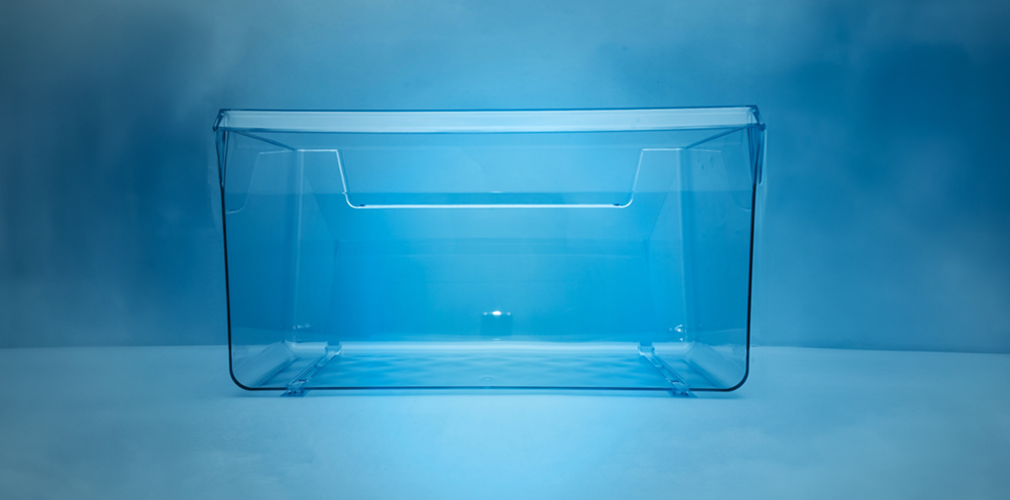

Injection Moulded Plastics

Mangal Industries' Injection Moulding business vertical is fully equipped to produce superior plastic components for a diverse range of industries, spanning Automotive, Consumer Durables, Home Appliances, Electronics, and Healthcare. Leveraging cutting-edge design principles, manufacturing technologies, and production practices, Mangal Industries delivers plastic components of varying sizes with uncompromising quality and precision.

Industries We Serve

Cutting-Edge Manufacturing

The integrated manufacturing facility has injection moulding machines ranging from 150T to 1200T covering an extensive size range. The fully automated manufacturing systems and processes allow us to deliver superior plastic components. The material feeding is done through centralized conveyor systems and parts handling through 3-axis & 6-axis robotics.

- Injection moulding machines ranging from 150T to 1200T covering an extensive size range.

- Automated operations with centralized conveyor and robotics parts handling.

- Expertise in processing wide plastic materials like PPCP, PC, PC+ABS, Nylon 30% GF and POM.

- Full-fledged Toolworks for mould design, manufacturing, and maintenance.

- Secondary operations include the hot plate welding assembly, hot sealing, ultrasonic and vibration welding, and screen printing.

Precision Engineering

Mangal Industries takes pride in its robust engineering capabilities, facilitating the rapid design and development of Injection Moulding parts to meet our customers' needs. Our team of engineers excels in utilizing cutting-edge design software, including AutoCAD Inventor, AutoCAD R16, SolidWorks, and Siemens NX12, ensuring efficiency and precision in every project.

Quality Assurance

Mangal’s quality systems are very robust and practised in true spirit to ensure that the products manufactured to meet customer specifications and application requirements. From raw materials to finished products, the comprehensive quality systems at Mangal ensures compliance with international standards. Through the Amara Raja Way ®, we aim to exceed the customers’ expectations.

To accomplish this, we focus on

- Agile business strategies with risk-based thinking and anticipating future trends

- Contemporary technologies and robust design principles

- Continuous enhancement of our engagement, development and performance

- Operational excellence through continual improvements

- Total employee involvement

- Fulfilling the compliance obligations

- Optimal utilization of energy and sustainable use of natural resources through the reduce, reuse and recycle concepts.

- Zero incidents, zero defects and zero breakdowns

Trusted by the Best: Our Esteemed Customers

*The logos and trademarks are the property of their respective owners.