At Mangal Toolworks, innovation and precision engineering converge to create exceptional tooling solutions. Our state-of-the-art Tool room is dedicated to crafting custom-made, premium-quality tools that cater to a wide range of industries and applications. With world-class manufacturing capabilities and a relentless commitment to international quality standards, we excel in delivering top-quality Poly/press Tools, Stamping Tools, Die-casting Dies and Injection Moulds.

Industries We Serve

Our Capabilities Help Bring

Innovation, From Concept To

Reality.

Mangal Toolworks stands as a leading force in the injection moulds and tooling industry, catering to the ever-evolving demands of the market. Our handpicked R&D and Engineering teams collaborate closely with our valued customers to craft tailored solutions for their specific needs. At the heart of our success lies a commitment to continuous innovation, enabling us to develop cutting-edge design solutions for a diverse range of industries and applications. We continuously invest in enhancing our manufacturing and engineering capabilities, striving to optimize processes, reduce lead times, and ensure maximum reliability in our products and services. With our unwavering dedication to excellence, Mangal Toolworks remains at the forefront of the new-age tooling industry.

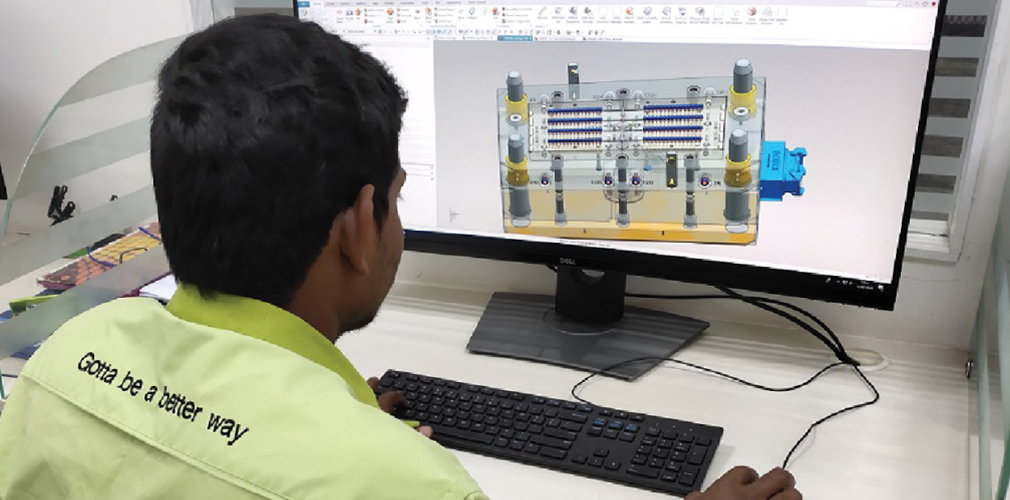

Tool Design Engineering

A dedicated team of domain experts for cutting-edge tool engineering

At Mangal Industries, we pride ourselves on delivering a comprehensive suite of engineering services that encompass product design & DFM, complete tool design, and cutting-edge 2D & 3D modelling. With our expertise, we bring your ideas to life, ensuring they align with efficient manufacturability and cost-effectiveness. Our meticulous approach guarantees seamless production processes, maximizing productivity and minimizing potential risks. The detailed visualizationsand accurate prototypes derived from our advanced modelling techniques empower you to make informed decisions and accelerate time to market.

Design & DFM

Tool Design

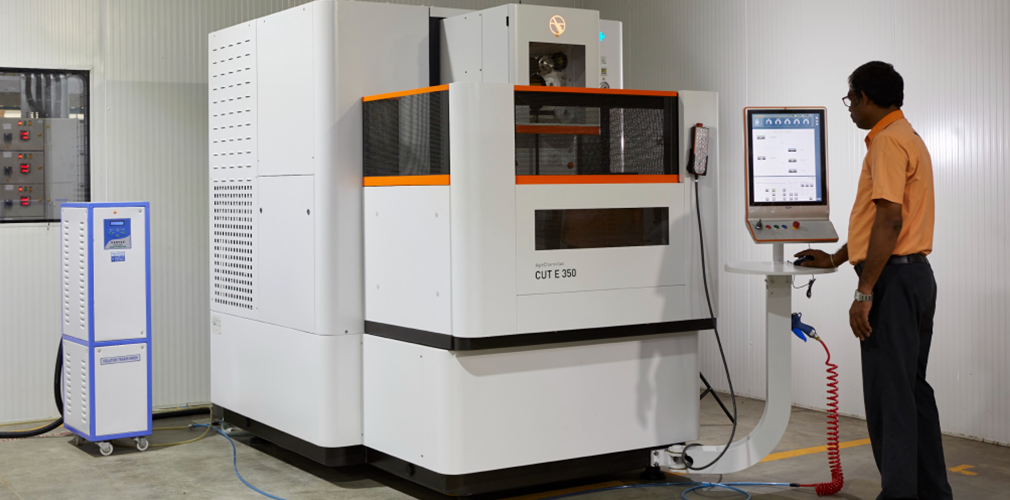

State-of-the-art Manufacturing

Empowering growth with advanced machinery & optimized processes

Mangal Industries possesses state-of-the-art machinery like CNC milling with 5-axis, 3-axis machines, CNC turning, Wire EDM/Sink EDM, and testing and validation facilities, which drive unmatched performance and efficiency. Consistency, accuracy, and repeatability are ingrained in Mangal's manufacturing process, consistently meeting and exceeding customer expectations. Mangal collaborates closely with customers to create tailor-made solutions that optimize manufacturability. From concept to implementation, Mangal Industries sets new precision engineering standards, empowering their customers' manufacturing success.

Project Management

The project management team serves as the crucial interface between Mangal and its customers. They ensure efficient and cost-effective project completion while mitigating risks. Coordinating project-specific activities, they diligently meet customer requirements, fostering harmonious communication throughout the project lifecycle. Their proactive problem-solving approach and attention to detail guarantee precise and timely delivery, building long-term partnerships based on trust and customer satisfaction.

Quality Assurance

Mangal Industries upholds a rigorous and genuine commitment to quality systems, ensuring that our products perfectly align with your business specifications and application needs. We leave no room for compromise, meticulously overseeing the entire manufacturing process from raw materials to finished products. Our comprehensive quality systems are designed to adhere to international standards, guaranteeing that our deliverables meet the highest levels of precision and excellence.

- In-Process Inspection Procedure

- Experience in First Article Verification (FAV) & Production Part Approval

- Processes (PPAP)

- Coordinate measuring machine to inspect the machined part and plastic components as well as for Reverse Engineering

Trusted Collaborators: Our Customer Partners

*The logos and trademarks are the property of their respective owners.